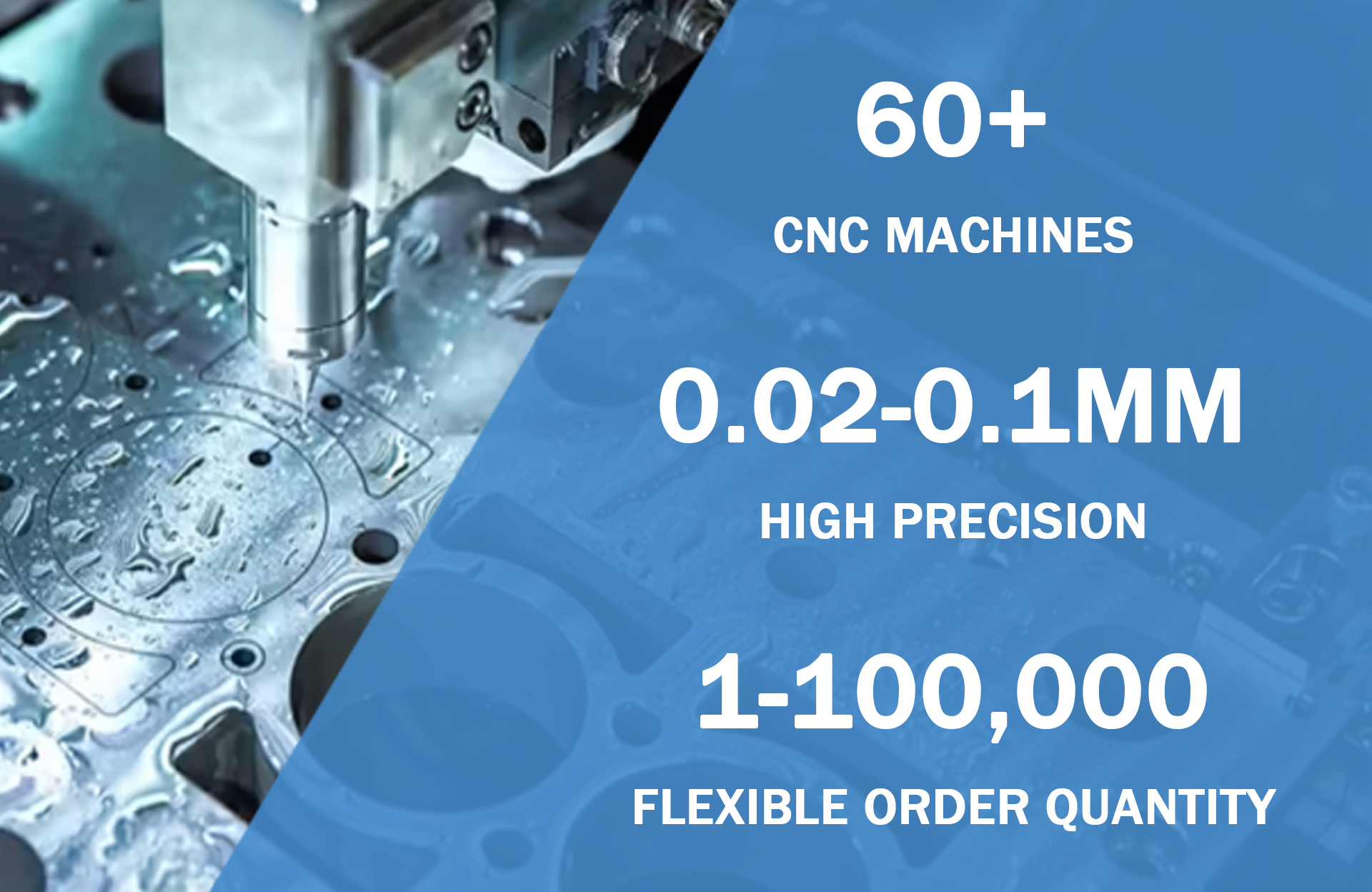

WHAT IS RAPID TOOLING?

Rapid tooling refers to the process of quickly manufacturing tools, such as molds or dies, to produce prototype parts or small production runs. It bridges the gap between rapid prototyping and traditional tooling methods, enabling faster and cost-effective production of parts compared to conventional tooling processes.

1、Direct Tooling 2、Soft Tooling 3、Bridge Tooling

ADVANTAGES OF RAPID TOOLING

1.Reduced Lead Times: Rapid tooling allows for the quick production of tools, significantly reducing lead times compared to traditional tooling methods. This rapid turnaround time is beneficial for meeting tight project deadlines.

2.Cost-Effectiveness: Rapid tooling is often more cost-effective than conventional tooling methods, especially for small production runs or prototyping. It helps in minimizing tooling costs and overall production expenses.

3.Flexibility: Rapid tooling offers flexibility in design iterations and modifications. It enables manufacturers to make quick adjustments to tooling to accommodate changes in part designs or requirements, facilitating agile manufacturing processes.

4.Customization: Rapid tooling allows for the production of customized tools tailored to specific project needs. This customization capability provides design flexibility and enables the creation of unique and intricate parts.

SERVE YOU THOROUGHLY

1

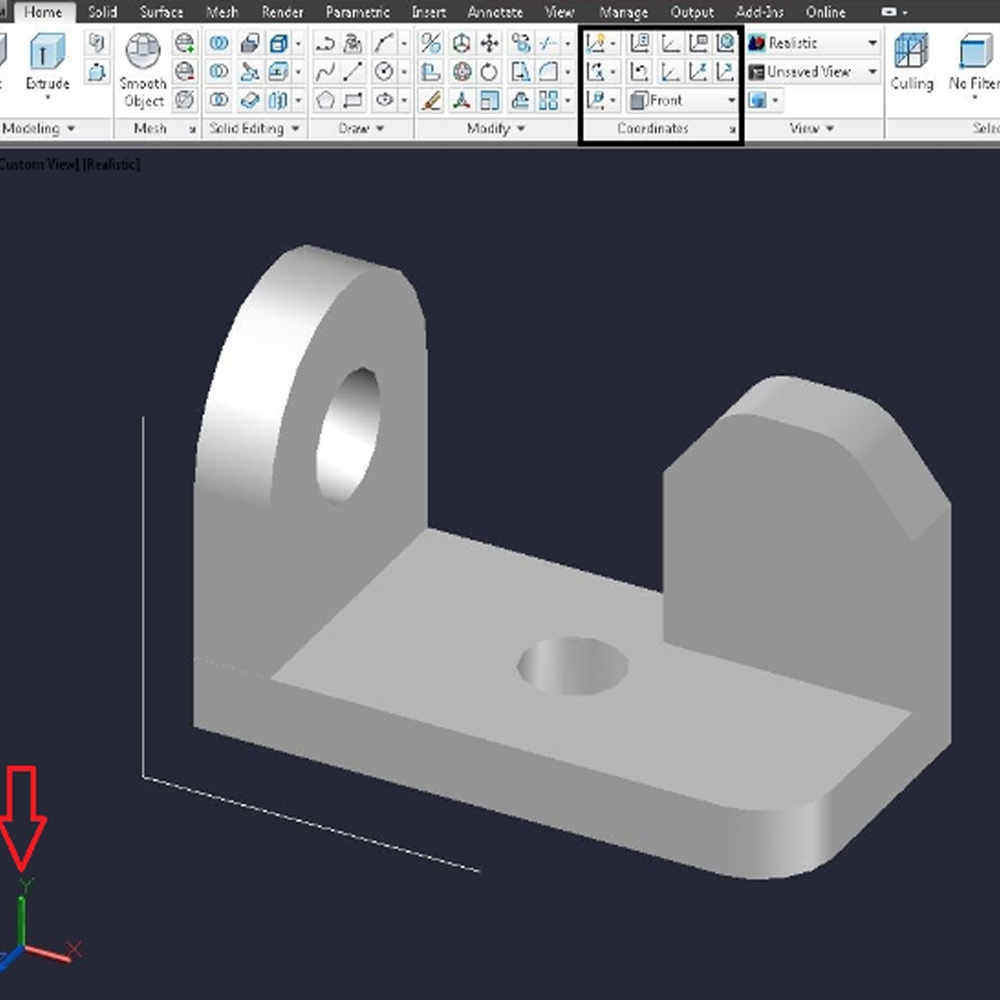

Provide 3D drawings

2

Confirm quotation

3

Sign the contract and pay the deposit

4

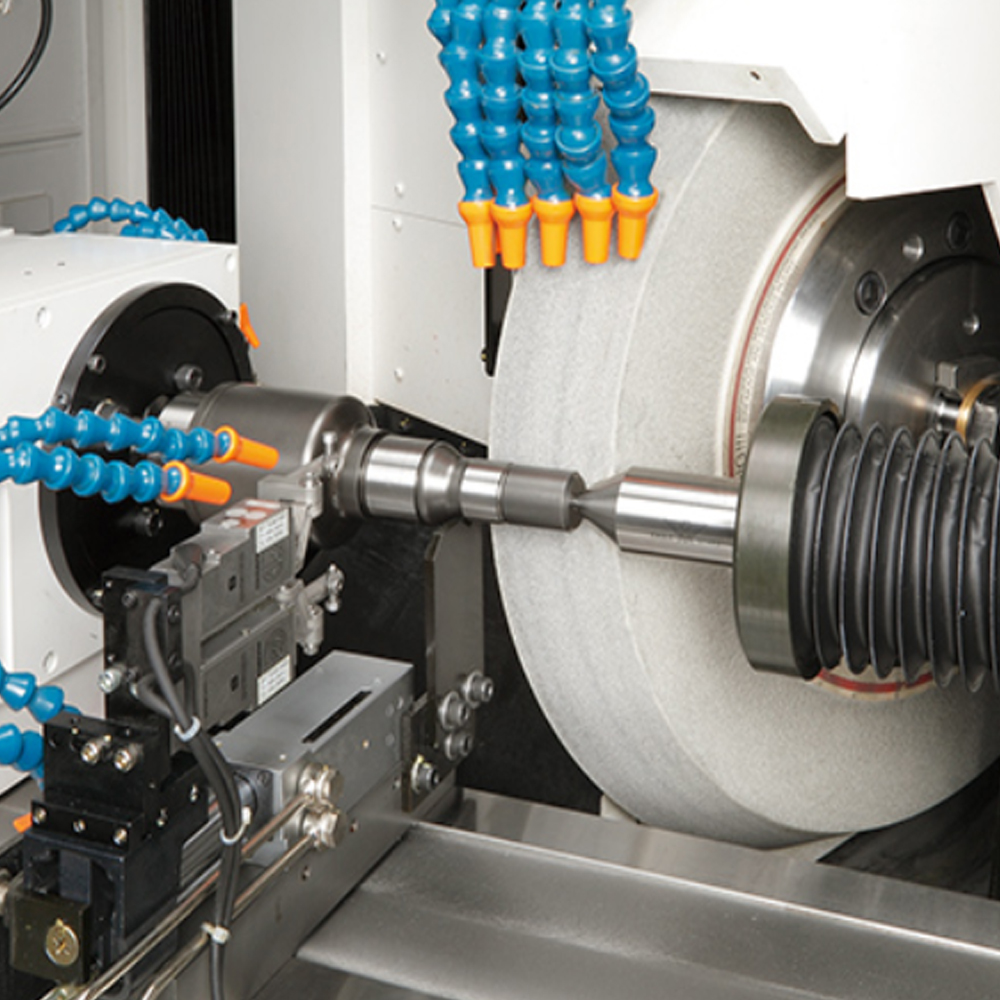

Customized production

5

Quality inspection and shipment

6

Delivery, payment of balance

7

Track logistics

8

After-sales service

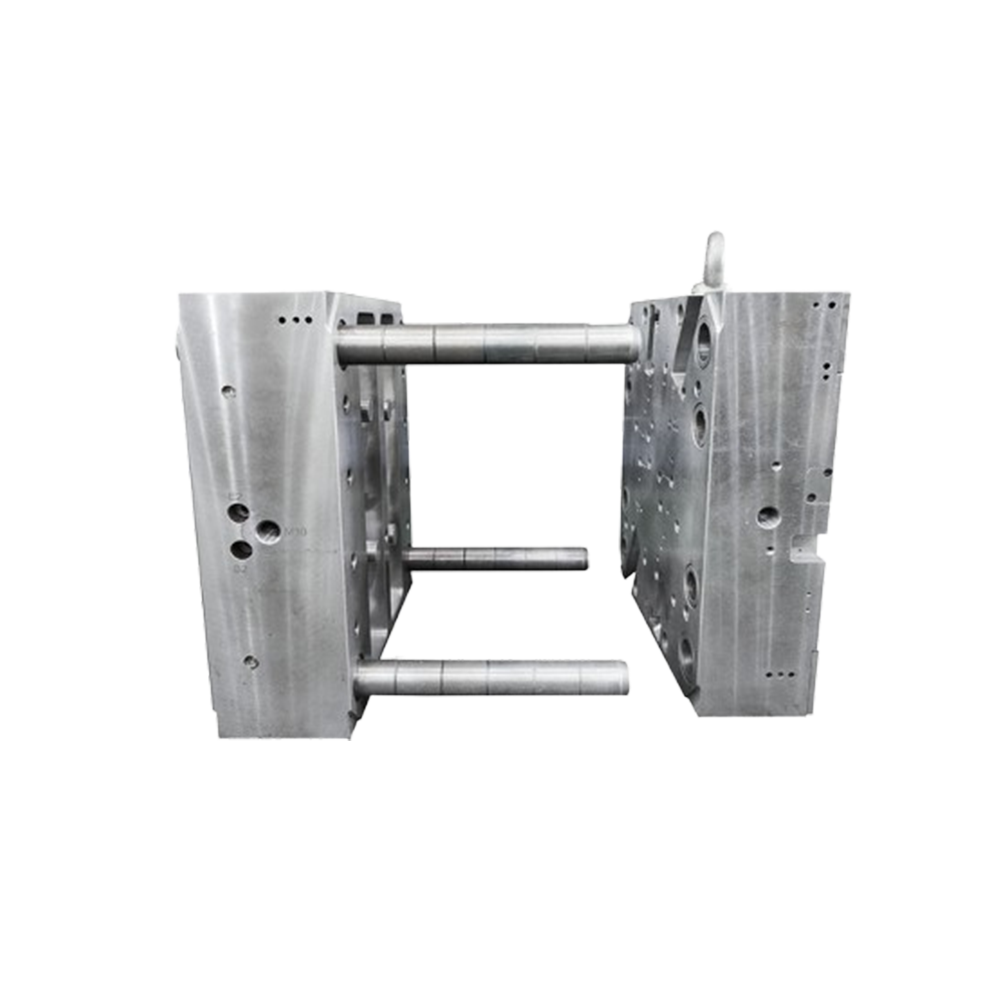

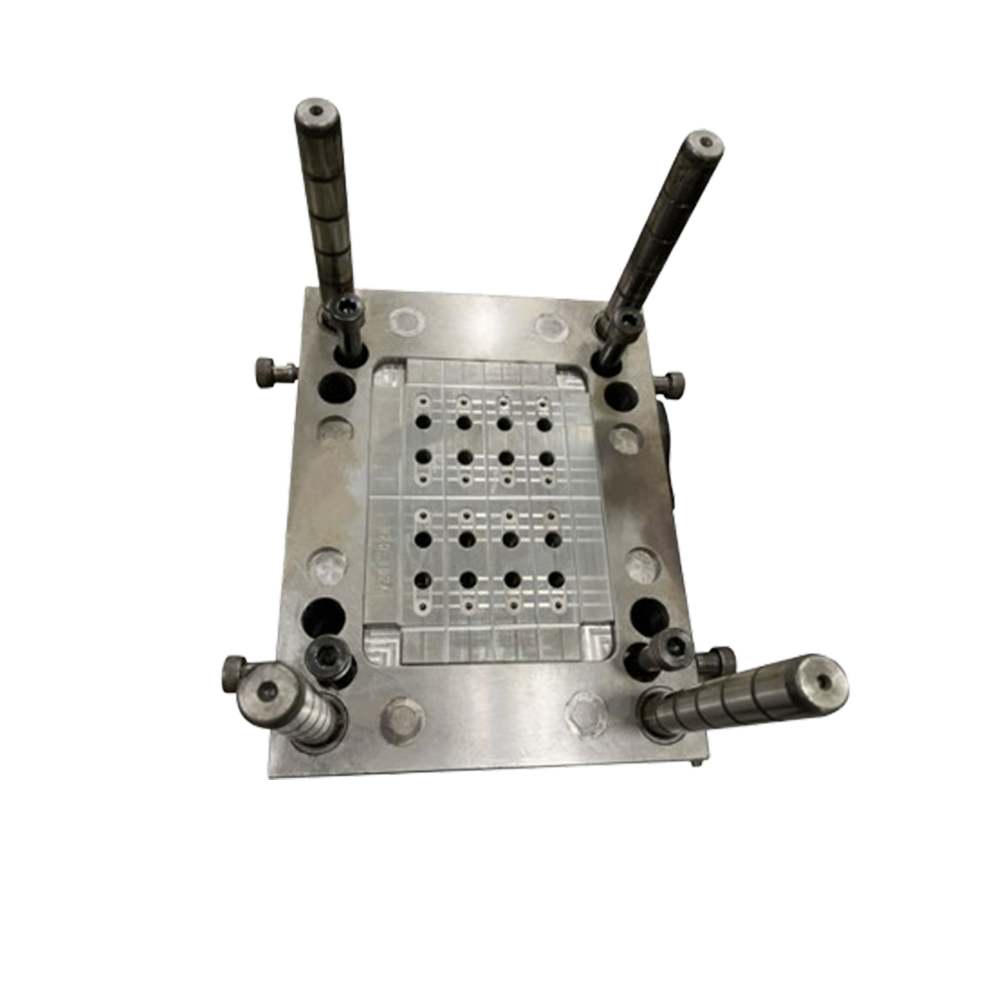

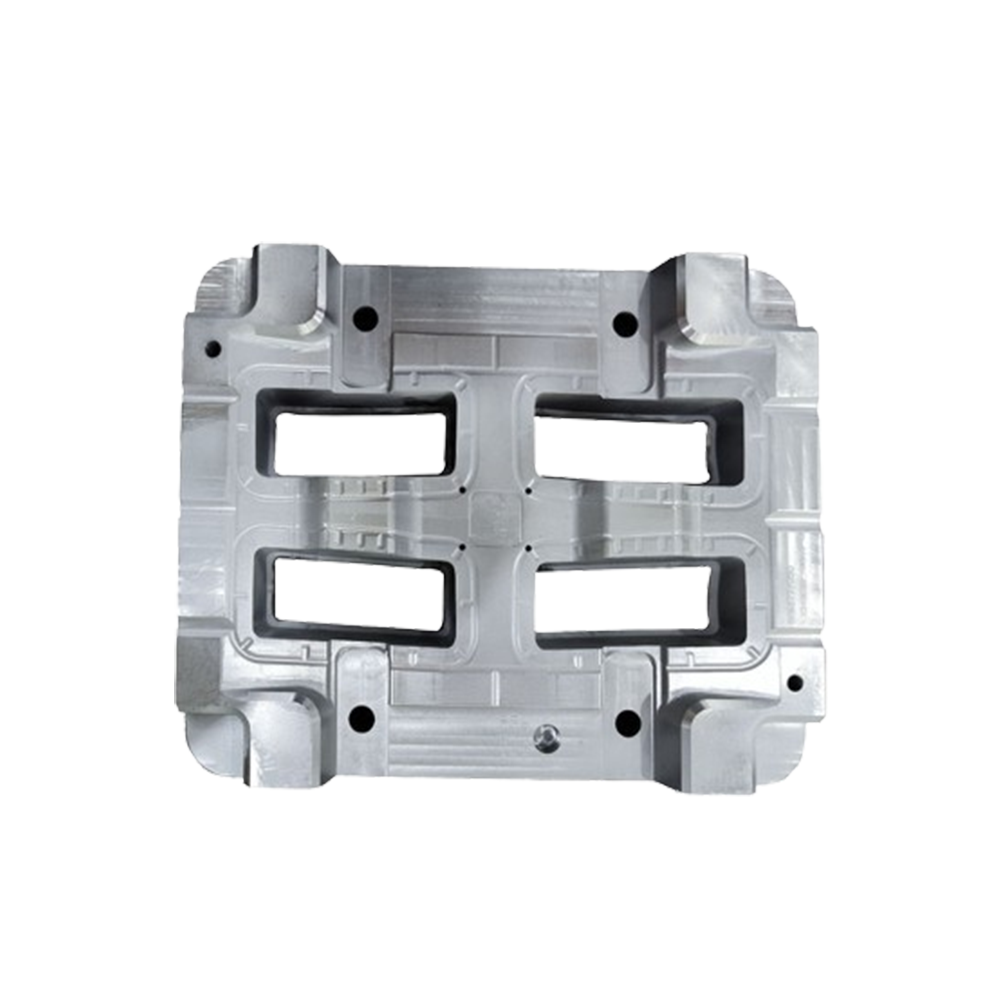

PRODUCT GALLERY