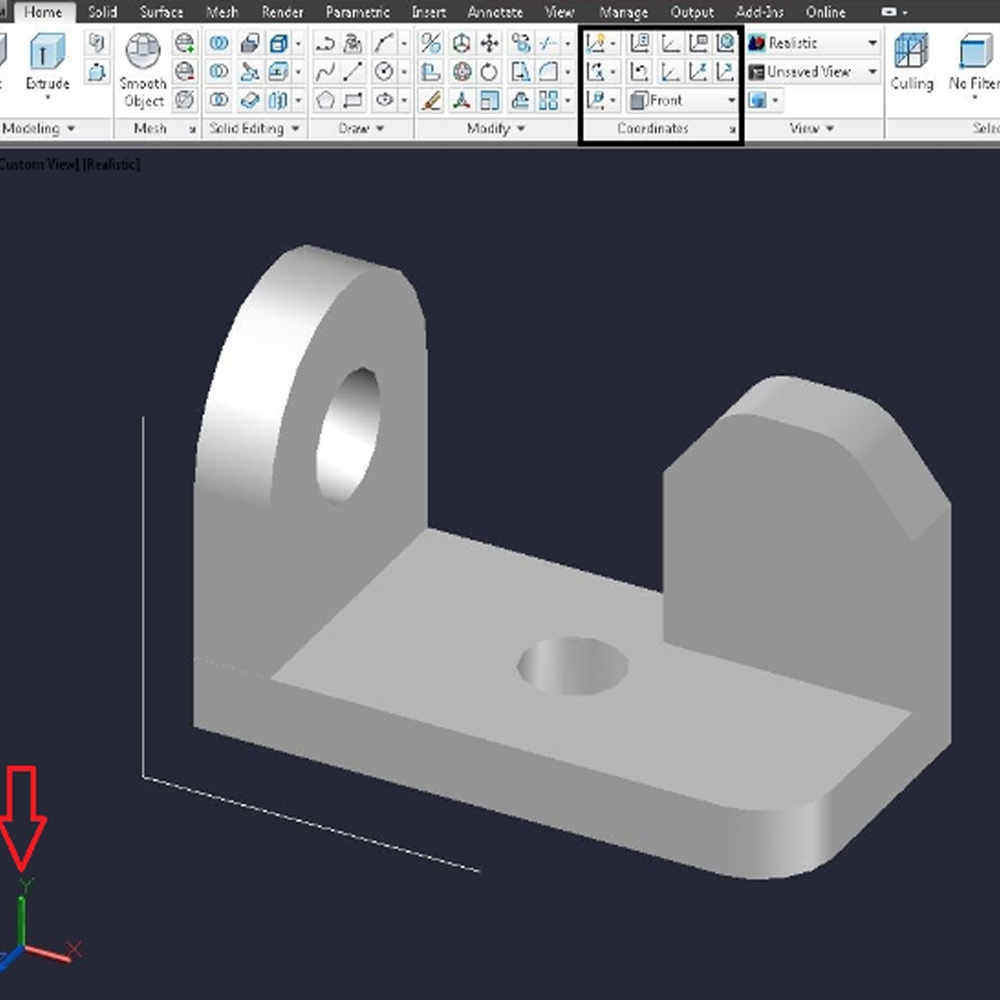

WHAT IS PROTOTYPE MACHINING ?

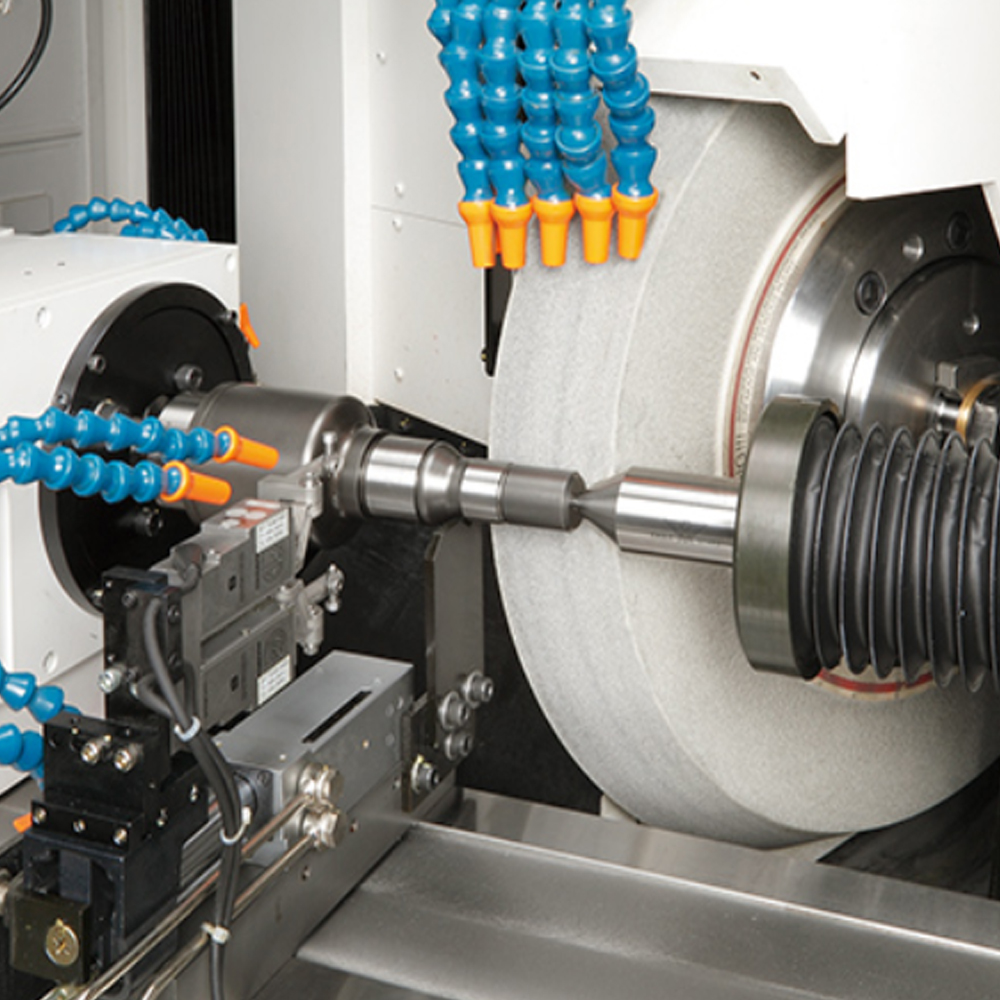

Prototype machining refers to the process of creating a prototype or a sample part using machining techniques such as milling, turning, drilling, or grinding. This process is typically used in product development to create a physical model of a product before mass production begins.

Prototype machining is crucial in the product development process as it helps in identifying any design flaws or issues early on, saving time and cost that would otherwise be incurred if these problems were discovered during mass production.

ADVANTAGES OF PROTOTYPE MACHINING

1、Faster Development: Creating prototypes through machining allows for quicker iterations and improvements compared to other methods. This speed can be crucial in getting a product to market sooner.

2、Cost-Effective: While machining prototypes can be more expensive than other rapid prototyping methods like 3D printing for larger quantities, it is often more cost-effective for producing a few high-quality prototypes.

3、Material Flexibility: Machining allows for the use of a wide range of materials, including metals, plastics, and composites, providing a more accurate representation of the final product’s properties.

4、High Precision: Machining processes offer high accuracy and precision, making it ideal for creating detailed and complex prototypes that closely resemble the final product.

SERVE YOU THOROUGHLY

1

Provide 3D drawings

2

Confirm quotation

3

Sign the contract and pay the deposit

4

Customized production

5

Quality inspection and shipment

6

Delivery, payment of balance

7

Track logistics

8

After-sales service

CONTACT US

EASY COMMUNICATION,HIGHT QUALITY,HIGH PRECISION ,FAST DELIVERY.GOT THE QUOTATION

PRODUCT GALLERY