WHAT IS PRECISION MACHINING ?

Precision machining refers to a manufacturing process that produces highly precise and intricate parts or components with tight tolerances. It involves the use of specialized machining techniques and tools to remove material from a workpiece and create the desired shape, size, and finish.

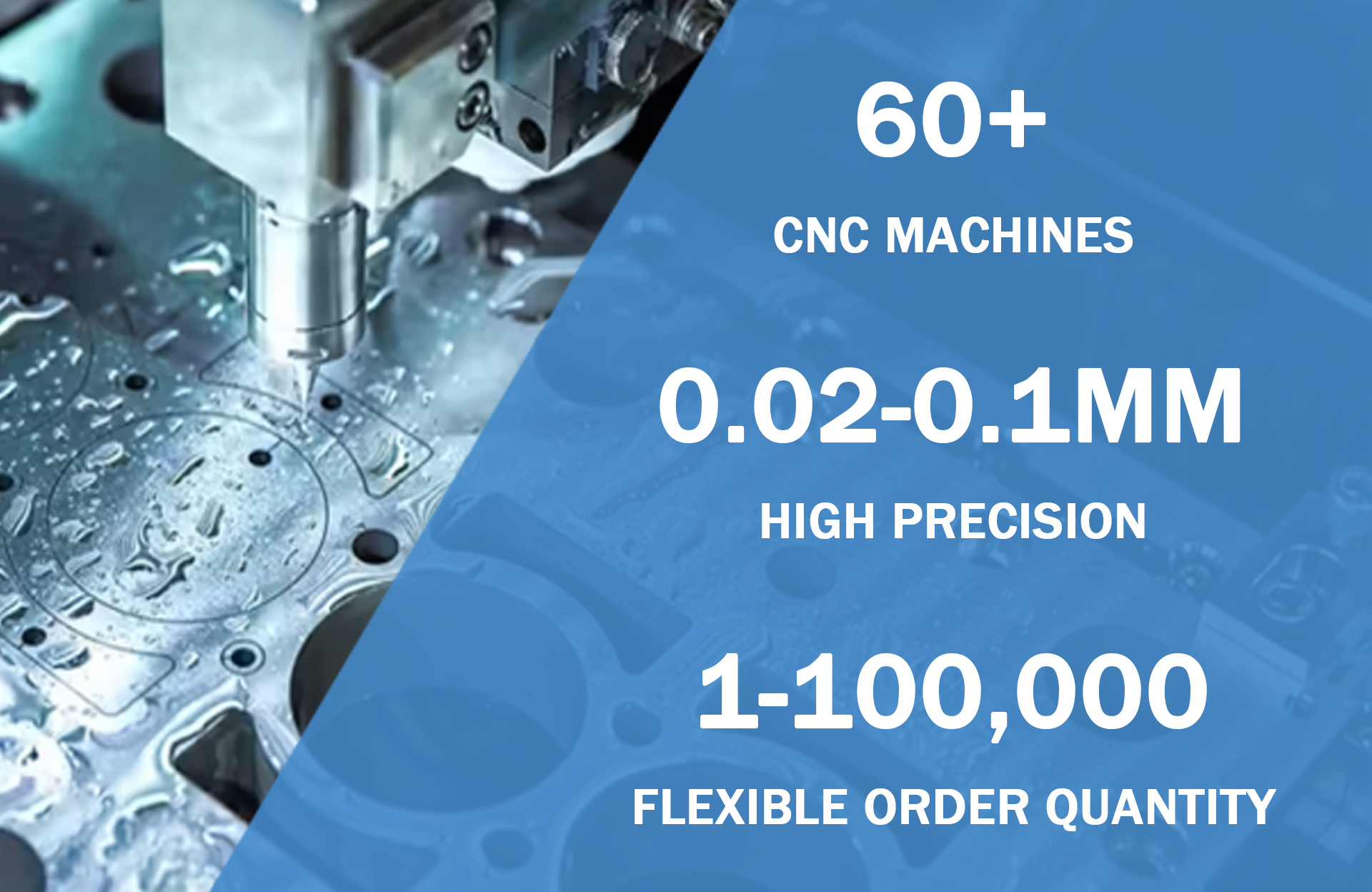

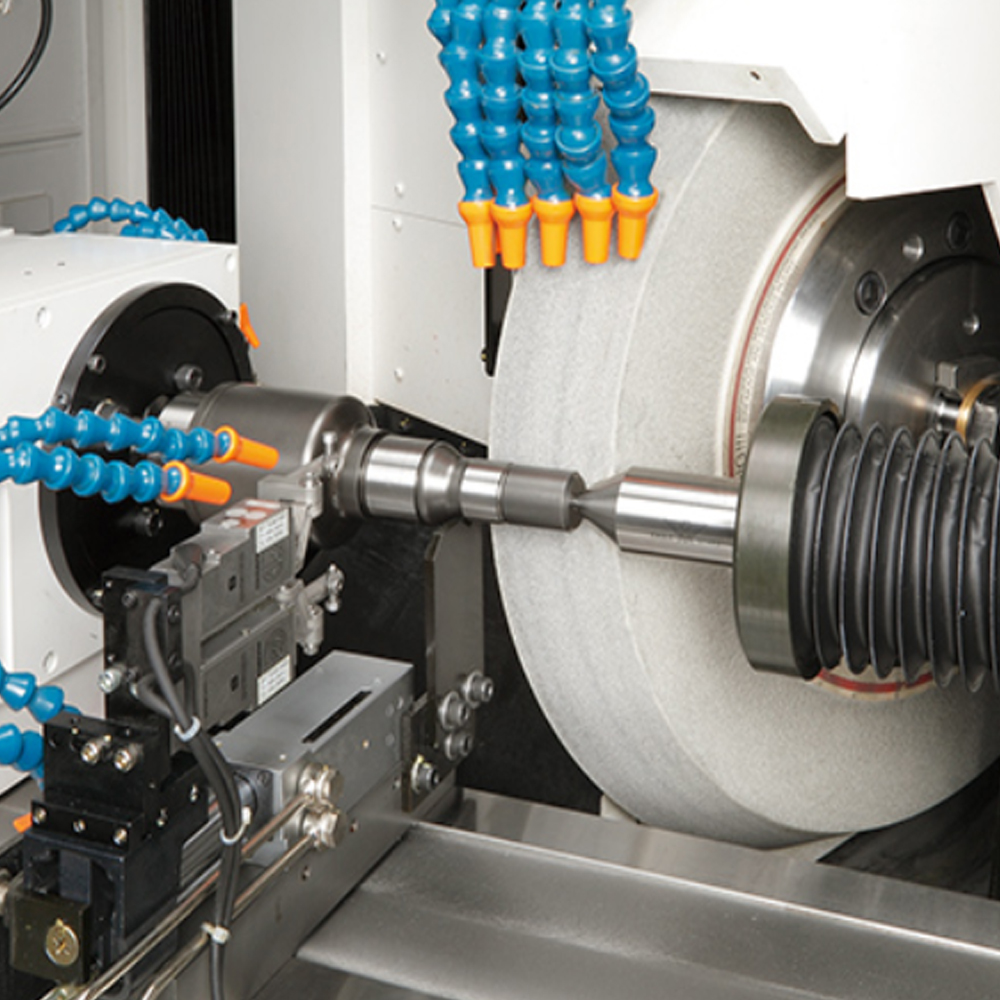

Precision machining involves the use of advanced machinery such as CNC (Computer Numerical Control) machines, lathes, milling machines, grinders, and other tools operated by skilled machinists. These machines are programmed to perform specific cuts and operations with high precision, ensuring that the final product meets the required specifications.

ADVANTAGES OF PRECISION MACHINING

1. High Accuracy: Precision machining can achieve extremely tight tolerances, typically within a few thousandths or even micrometers. This level of accuracy ensures that the parts meet the specified dimensions and fit together precisely.

2. Complex Geometries: Precision machining enables the production of intricate and complex shapes that may be challenging or impossible to achieve with other manufacturing methods. This capability allows for the creation of custom or specialized parts for various applications.

3. Consistency and Repeatability: Precision machining processes, particularly those performed on CNC machines, offer excellent repeatability. The same part can be replicated multiple times with consistent accuracy, ensuring uniformity in production.

4. Wide Range of Materials: Precision machining can work with a wide range of materials, including metals, plastics, composites, and exotic alloys. This versatility allows for the production of parts for diverse industries and applications.

SERVE YOU THOROUGHLY

1

Provide 3D drawings

2

Confirm quotation

3

Sign the contract and pay the deposit

4

Customized production

5

Quality inspection and shipment

6

Delivery, payment of balance

7

Track logistics

8

After-sales service

CONTACT US

EASY COMMUNICATION,HIGHT QUALITY,HIGH PRECISION ,FAST DELIVERY.GOT THE QUOTATION

PRODUCT GALLERY