WHAT IS METAL MACHINING?

Metal machining is a manufacturing process that involves shaping metal workpieces using various cutting tools and techniques. This process removes material from a metal workpiece to achieve the desired shape, size, and surface finish. Metal machining operations can include turning, milling, drilling, grinding, and electrical discharge machining (EDM), among others.

ADVANTAGES OF METAL MACHINING

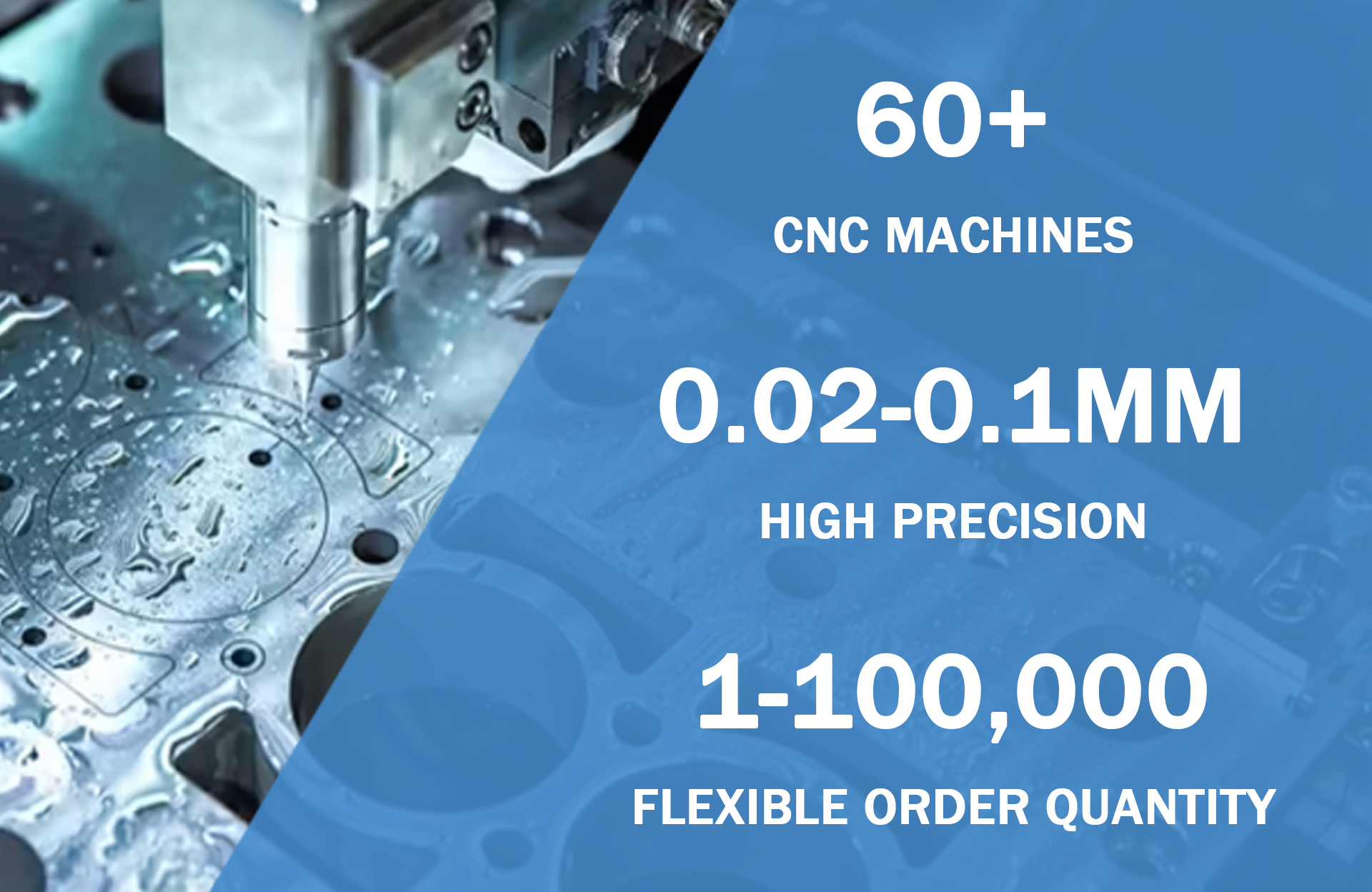

1. High precision: Machining processes can achieve tight tolerances and dimensional accuracy, ensuring precise and consistent metal parts.

2. Versatility: Metal machining can be utilized for a wide range of shapes, sizes, and complexities, making it suitable for various applications.

3. Strength and durability: Machined metal components are often known for their strength, durability, and resistance to wear and fatigue.

4. Surface finish: Machining processes can achieve excellent surface finishes, eliminating the need for additional finishing operations.

5. Material compatibility: Metal machining can be applied to a broad range of metals, allowing for flexibility in material selection.

SERVE YOU THOROUGHLY

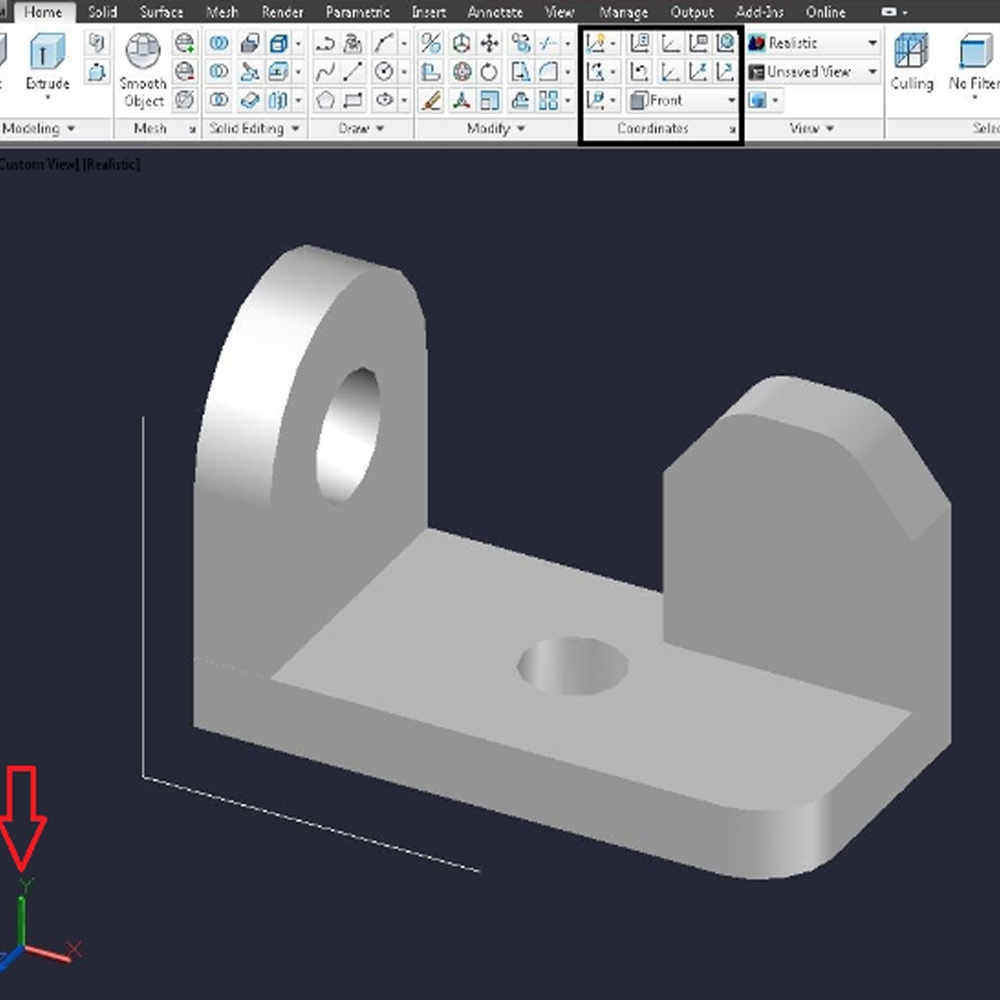

1

Provide 3D drawings

2

Confirm quotation

3

Sign the contract and pay the deposit

4

Customized production

5

Quality inspection and shipment

6

Delivery, payment of balance

7

Track logistics

8

After-sales service

MATERIALS FOR METAL MACHINING

| Materials | Name |

|---|---|

| Metal | Aluminum_1050 |

| Metal | Aluminum_1060 |

| Metal | Aluminum_2024 |

| Metal | Aluminum_5052_H11 |

| Metal | Aluminum_5083 |

| Metal | Aluminum_6061 |

| Metal | Aluminum_6082 |

| Metal | Aluminum_7075 |

| Metal | Aluminum_bronze |

| Metal | Aluminum_MIC_6 |

| Metal | Aluminum_QC_10 |

| Metal | Brass |

| Metal | Copper |

| Metal | Copper_beryllium |

| Metal | Copper_chrome |

| Materials | Name |

|---|---|

| Metal | Copper_tungsten |

| Metal | Magnesium |

| Metal | Magnesium alloy |

| Metal | Phosphor bronze |

| Metal | Steel_Stainless 303 |

| Metal | Steel_Stainless 304 |

| Metal | Steel_Stainless 316 |

| Metal | Steel_Stainless 410 |

| Metal | Steel_Stainless 431 |

| Metal | Steel_Stainless 440 |

| Metal | Steel_Stainless 630 |

| Metal | Steel 1040 |

| Metal | Steel 45 |

| Metal | Steel D2 |

| Metal | Tin bronze |

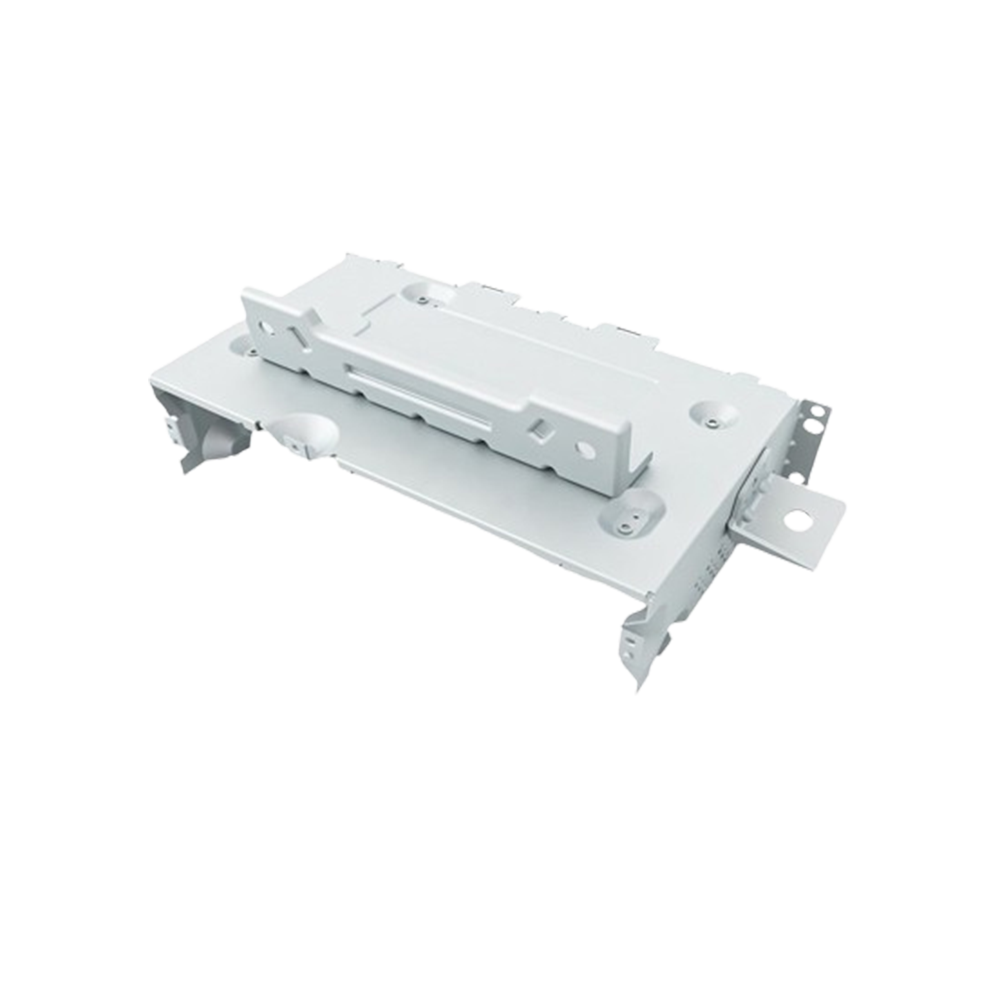

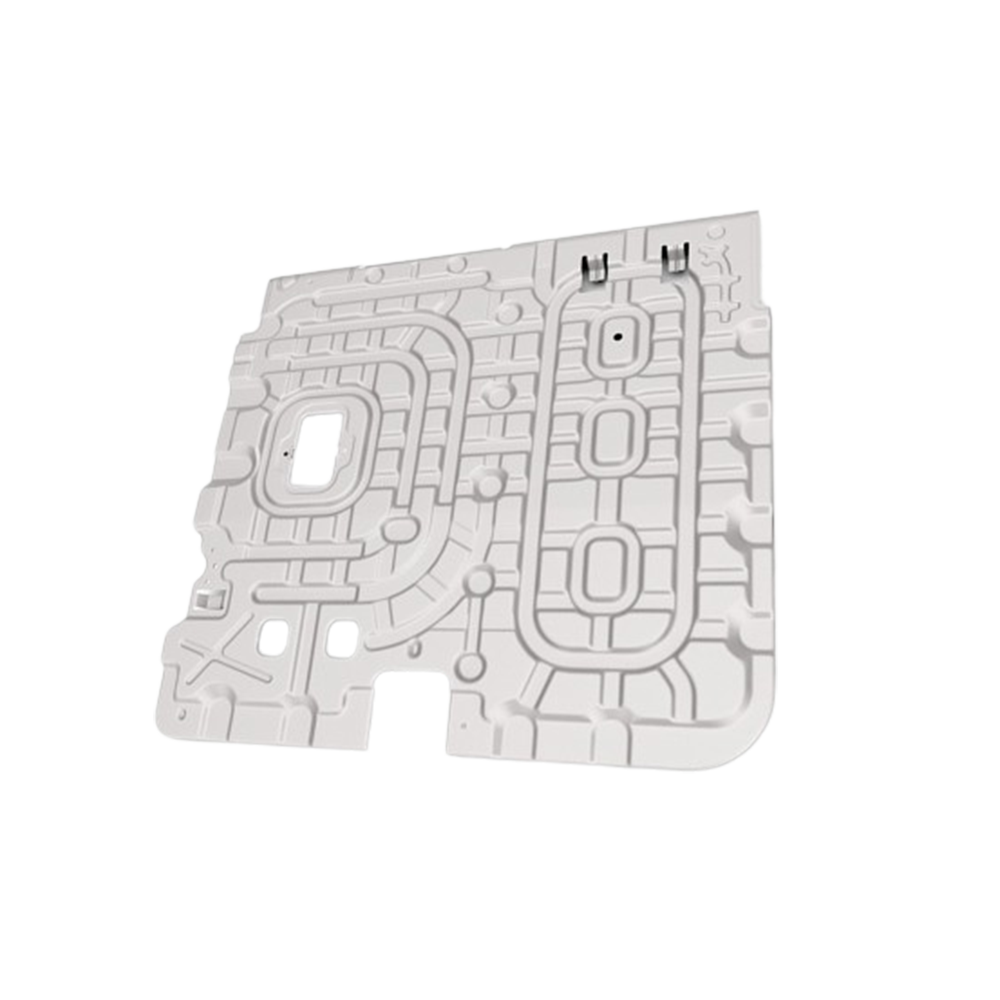

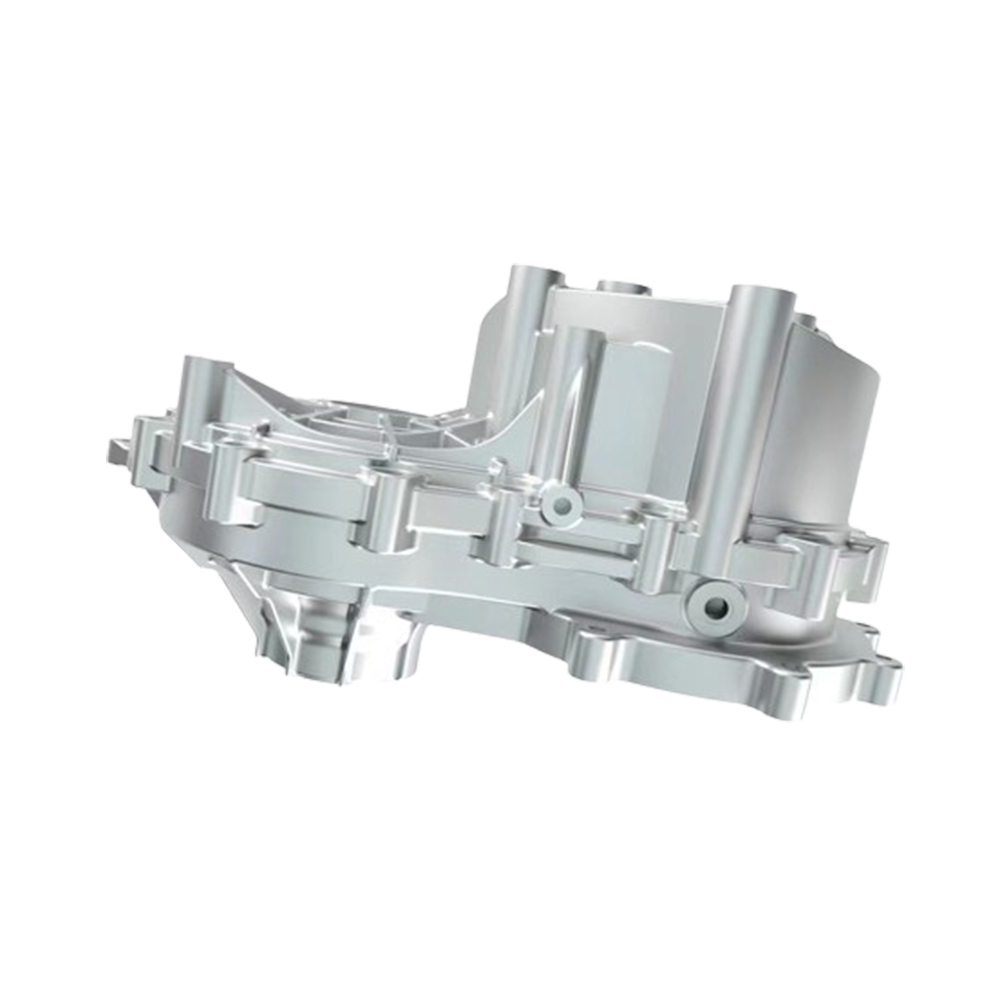

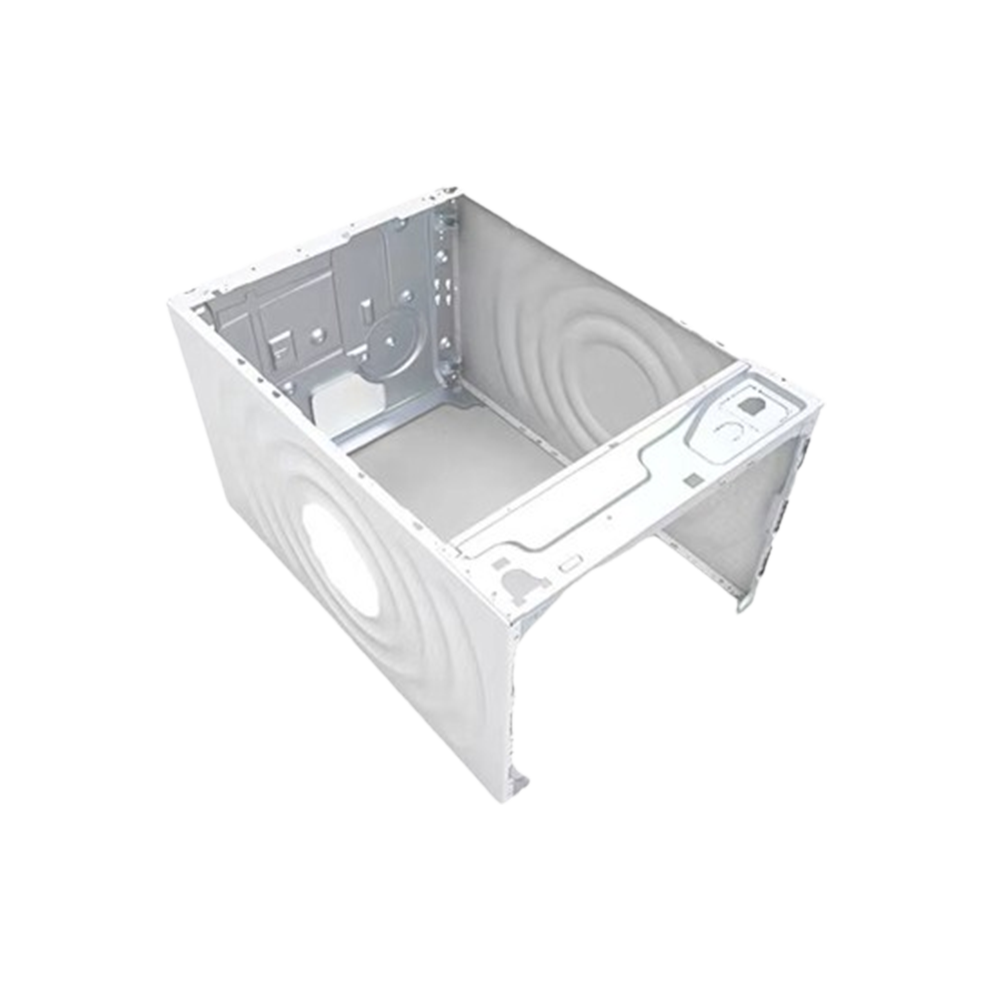

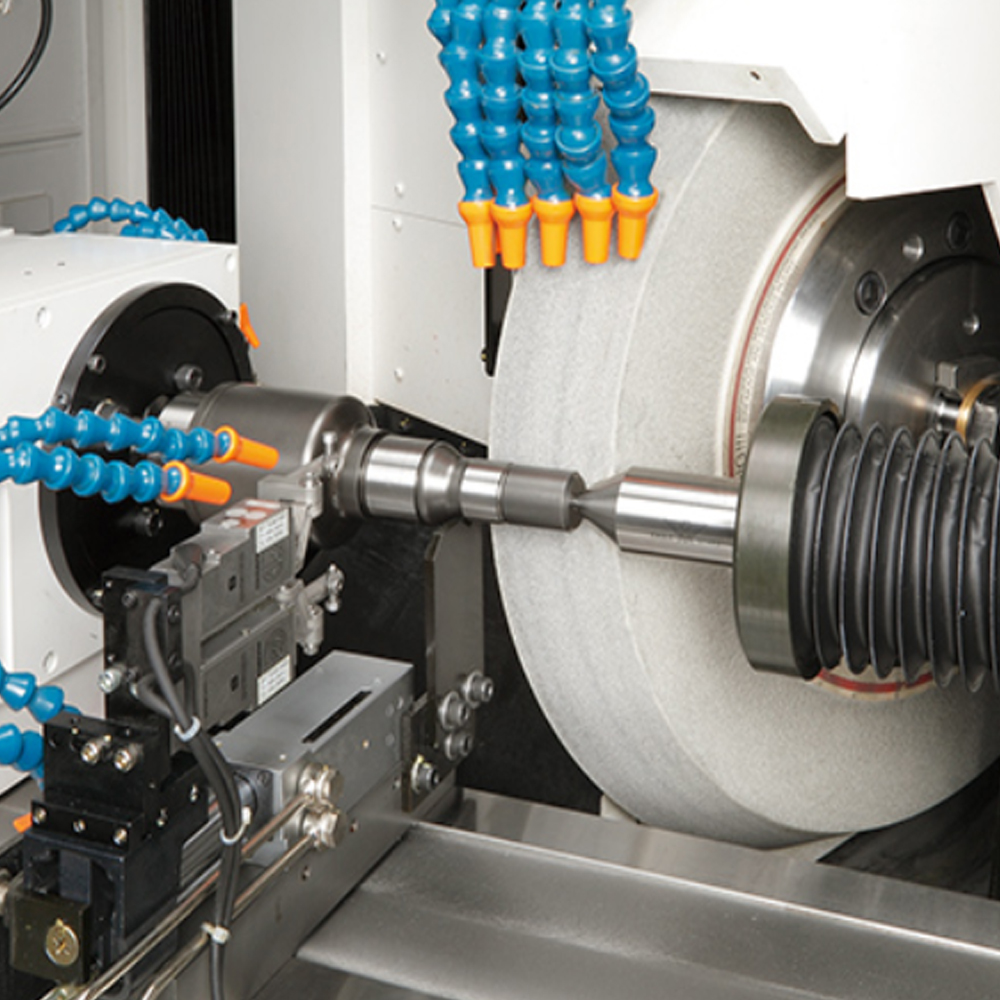

PRODUCT GALLERY