WHAT IS PLASTIC MACHINING?

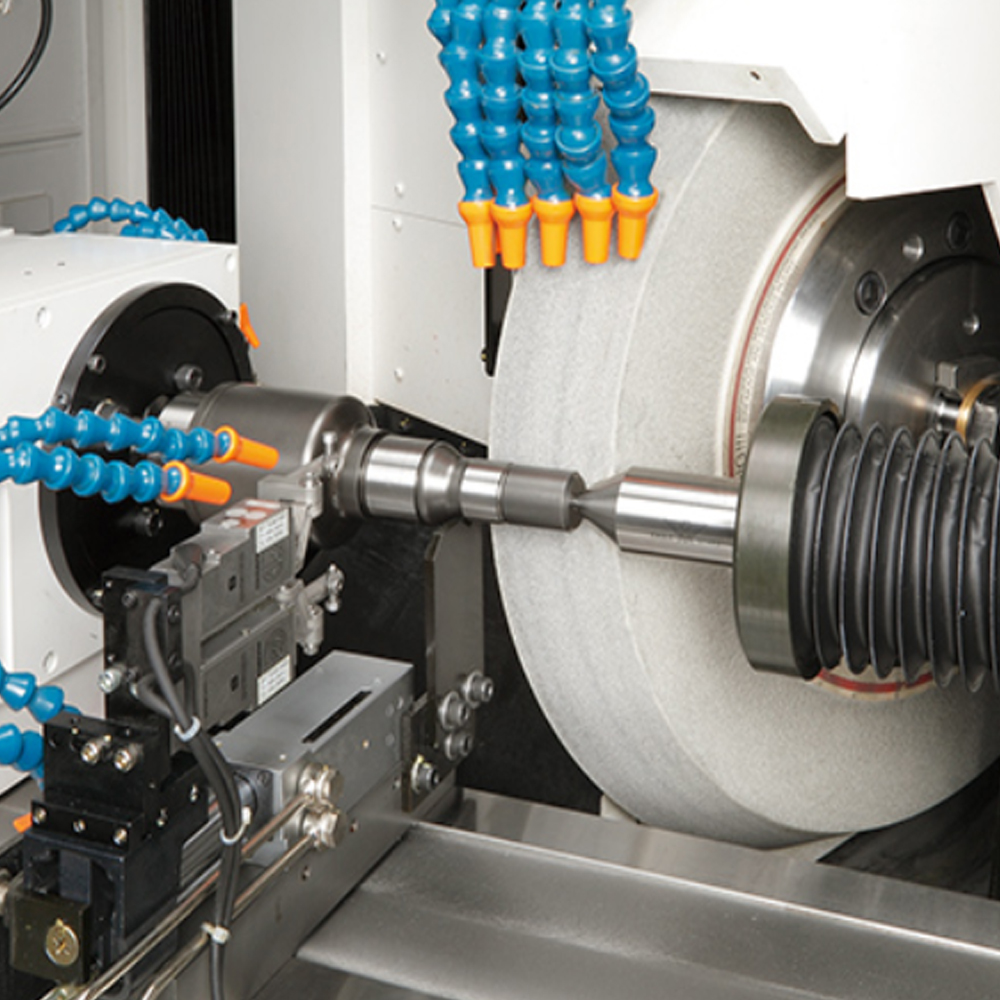

Plastic machining refers to the process of using specialized tools and techniques to shape and finish plastic materials into desired forms or products. This process involves cutting, drilling, milling, turning, and other methods to create precise and complex shapes from plastic materials.

Plastic machining is commonly used in industries where precision and customization are essential, such as in manufacturing, aerospace, automotive, electronics, and medical device production.

ADVANTAGES OF PLASTIC MACHINING

1. Precision and Customization: Plastic machining allows for the production of highly precise parts with tight tolerances. It enables customization and flexibility in design, allowing for the creation of complex shapes, features, and sizes tailored to specific requirements.

2. Wide Range of Plastic Materials: Plastic machining can work with a variety of plastic materials, each offering different properties and characteristics. This allows for the selection of the most suitable material for the intended application, such as for mechanical strength, chemical resistance, or electrical insulation.

3. Versatility and Adaptability: Machining techniques can be applied to various plastic materials and can accommodate a range of part sizes and geometries. This versatility makes plastic machining suitable for producing parts for diverse industries and applications.

4. Cost-Effective for Small to Medium Production Runs: Plastic machining can be a cost-effective manufacturing method for small to medium production runs, particularly when compared to tooling and molding processes required for large-scale production. It eliminates the need for expensive molds or dies, making it more economical for low-volume or custom orders.

SERVE YOU THOROUGHLY

1

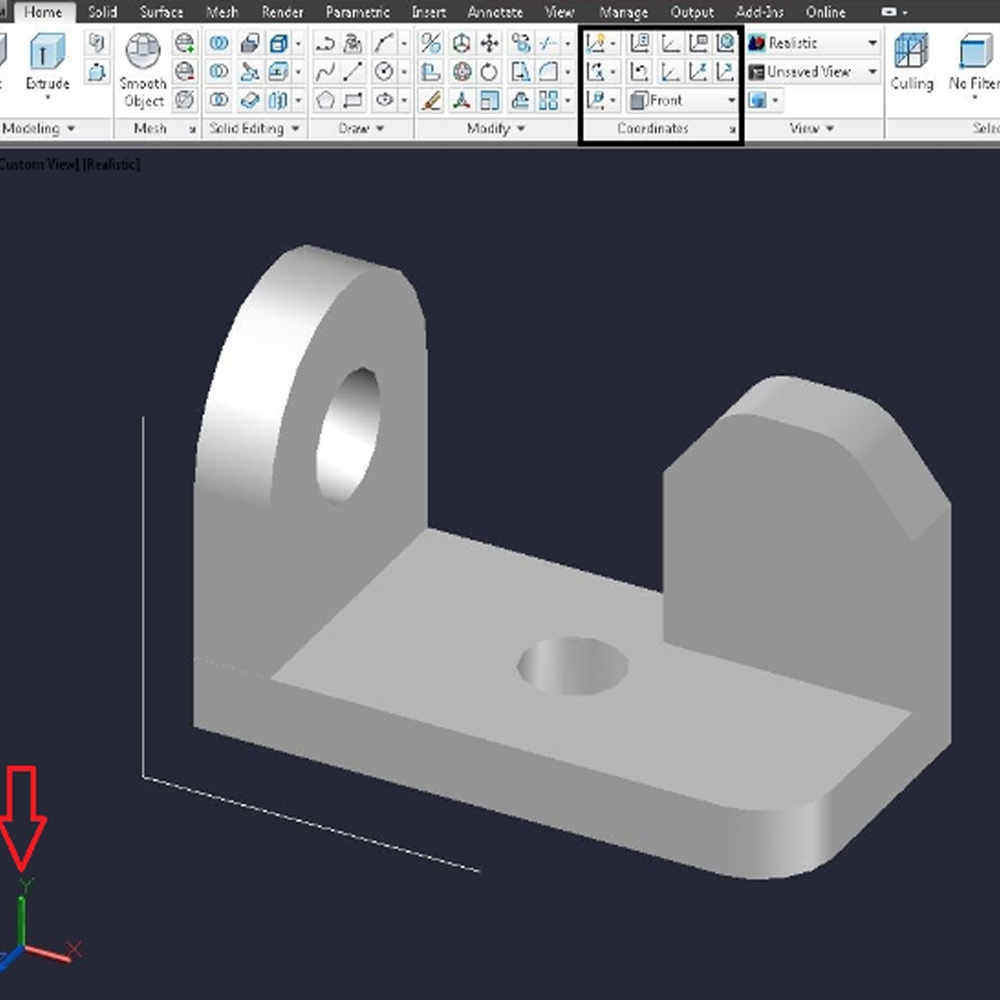

Provide 3D drawings

2

Confirm quotation

3

Sign the contract and pay the deposit

4

Customized production

5

Quality inspection and shipment

6

Delivery, payment of balance

7

Track logistics

8

After-sales service

MATERIALS FOR PLASTIC MACHINING

| Materials | Name |

|---|---|

| Plastic | Acrylonitrule butadiene styrene |

| Plastic | Acrylonitrule butadiene styrene+Polycarbonate |

| Plastic | High_density polyethylene |

| Plastic | Nylon 6 |

| Plastic | Nylon 6 + 30% Glass Fill |

| Plastic | Nylon 6_6 +30% Glass Fill |

| Plastic | Nylon 6_6 Polyamide |

| Plastic | Polybutylene terephthalate |

| Plastic | Polycarbonate |

| Plastic | Polycarbonate_Glass Fill |

| Plastic | Polycarbonate+ 30% Glass Fill |

| Plastic | Polyether ether ketone |

| Plastic | Polyetherimide |

| Materials | Name |

|---|---|

| Plastic | Polyetherimide + 30% Glass Fill |

| Plastic | Polyetherimide + Ultem 1000 |

| Plastic | Polyethylene |

| Plastic | Polyethylene terephthalate |

| Plastic | Polymethyl methacrylate _ acrylic |

| Plastic | Polyoxybenzylmethylenglycolanhydride |

| Plastic | Polyoxymethylene |

| Plastic | Polyphenylene sulfide |

| Plastic | Polyphenylene sulfide + Glass Fill |

| Plastic | Polyphenylsulfone |

| Plastic | Polypropylene |

| Plastic | Polyvinyl chloride |

| Plastic | Polyvinyl chloride + White/Grey |

| Plastic | Polyvinylidene fluoride |

PRODUCT GALLERY